Macroscopic Draping Simulation for Non-Crimp Fabrics (NCF)

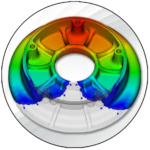

Modeling draping on the macroscopic level is essential for efficiently simulating industrial-scale components. Most simulations of NCF have been conducted at the mesoscopic level, where the fibers and the stitching are captured discretely. More recently, NCF models have also been developed at the macroscopic level by KIT-FAST and made available through SimuDrape. This macroscopic approach for NCF draping simulation has been adopted in the public-funded project ELECTRA and applied to a complexly shaped aerospace structure.